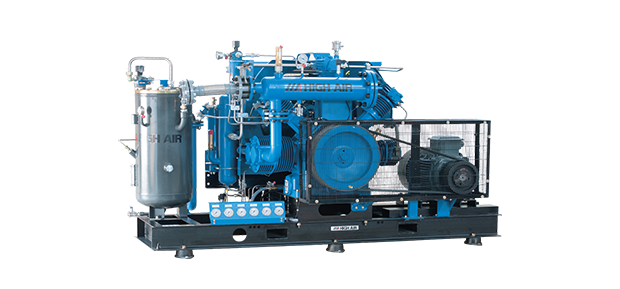

HEM/HE Series Helium/Argon Compressors

HEM/HE Series Helium/Argon Compressors are widely used in helium/argon recovery, helium/argon filling, and other industries. Whether it's industrial-grade helium/argon or high-purity helium/argon, whether you need a filling compressor or a complete recovery system, High Air can provide tailor-made solutions for you.

*High Air has designed special blocks for helium/argon, adopting a dual-shaft seal design and a pressure- retaining

crankcase to prevent gas leakage. The multi-stage compression design effectively reduces the exhaust temperature at each stage, thus extending the unit's lifespan.

*Specifically selected gas valves for helium/argon compression ensure efficient and reliable long-term operation.

*Special drantage recovery and venting recovery systems effectively prevent the waste of rare gases.

*Dedicated high-pressure filtration and purification systems designed for helium/argon ensure low oil and water content in the exhaust, meeting the requirements for high-purity helium filling.

*Air-cooled/water-cooled designs meet various application needs.

*Electric motor/diesel engine drive for all-weather operation.

*Multiple models to meet different demands.

These compressors are specially designed for helium/argon applications and are equipped with features to optimize efficiency, reliability, and purity for various helium/argon processes.

Design Features

Our standardized modular design offers more flexibility and convenience in adjusting pistons, cylinders, cylinder heads, and valve components, enabling us to provide customers with efficient and economical systems. The design characteristics and advantages of our units ensure their enduring performance and gain approval from users.

*Easy installation and maintenance

*Low maintenance requirements and operating costs

*No special foundation requirements

*Venting recovery system to eliminate gas leakage

*Maximum operating pressure up to 350Bar

*Well-balanced design

*Low vibration

*Low compression ratio and temperature rise

*Suitable for continuous or intermittent operation

*Low operating speed for extended lifespan

*Optional direct-drive configuration

*Optional silent unit design or containerized design

These features make our units capable of withstanding the test of time and being highly regarded by our customers. The combination of ease of installation, low maintenance, and long-lasting performance makes our systems a reliable choice for various industrial applications.

| Model | Pressure Bar | Flow m3/min | Power kw | Dimensions mm | Weight kg |

| HEM15-200 | 200 | 15 | 7.5 | 100*720*1365 | 266 |

| HEM25-200 | 200 | 25 | 15 | 1400*850*1660 | 500 |

| HE50-200 | 250 | 50 | 22 | 2055*1000*1200 | 600 |

| HE100-200 | 200 | 100 | 45 | 2875*1300*1600 | 2200 |

| HE150-200 | 200 | 150 | 75 | 2875*1300*1600 | 2250 |

| HE200-200 | 200 | 200 | 90 | 3300*2100*2000 | 5200 |

| HE300-200 | 200 | 300 | 132 | 3300*2100*2000 | 5400 |

| |||||

HE200-200 Cabinet HE100-200 Silent