NA Series Booster Compressors

NA Series Compressors, offering you an integrated solution, are suitable for various boosting applications. Whether it's pressure swing adsorption nitrogen generation, membrane separation nitrogen generation, or direct supply from nitrogen cylinders, they can seamlessly integrate with our boosting systems.

*No need to depressurize the gas source intake pressure, directly boosting to avoid increased energy consumption caused by intake depressurization, ensuring efficient compression of every unit of gas.

*Wide operating temperature range from -10 to 45¡ãC, providing continuous mid-to-high-pressure gas supply in all seasons and regions.

*Various types of main units available, from single-stage to three-stage compression, offering optimal choices for different usage scenarios and pressure ratios.

*Fully air-cooled main unit design, eliminating the need for complex cooling water systems, saving valuable space, reducing initial investments, and installation costs significantly.

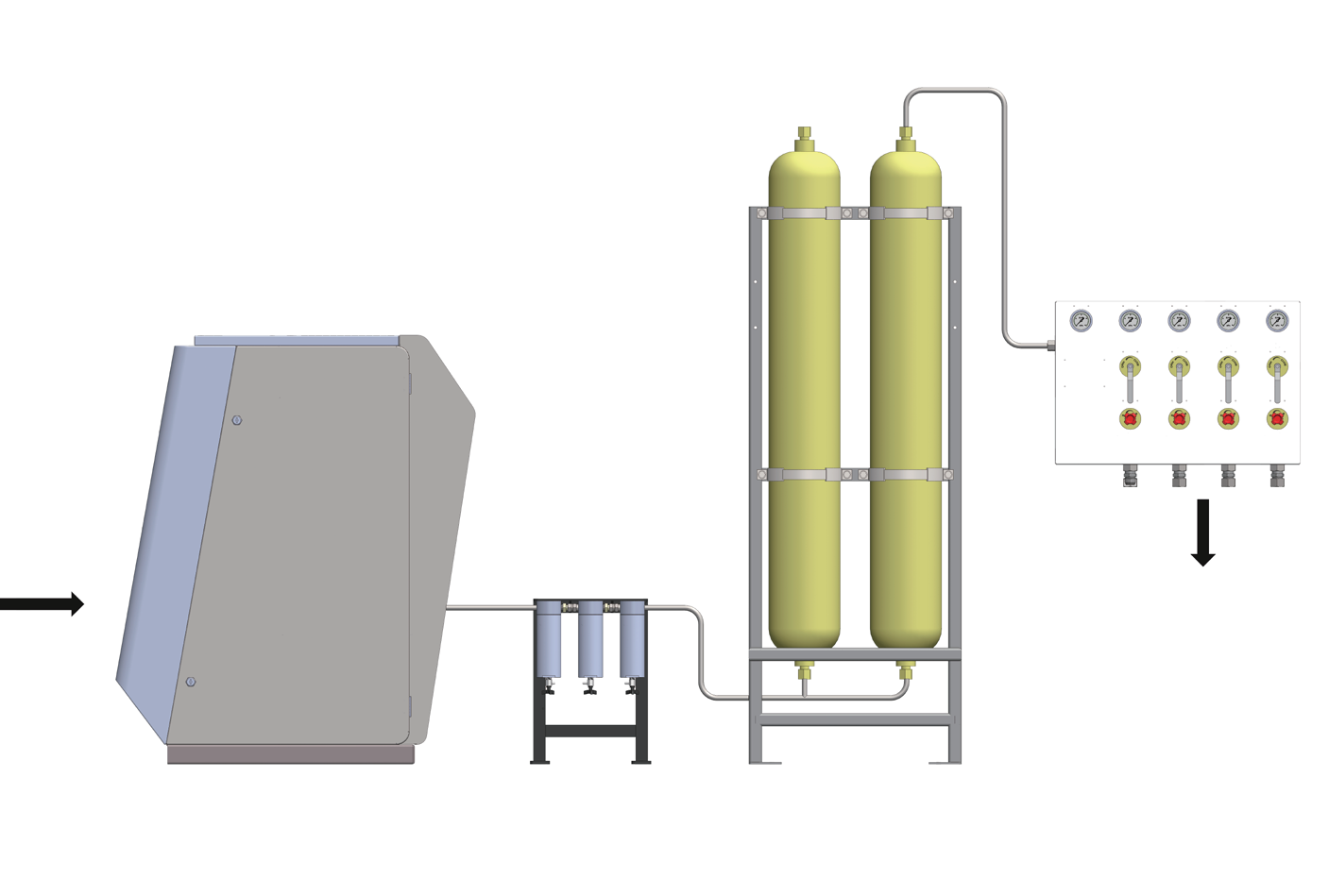

*The complete configuration system includes an intake buffer tank, booster, gas storage system, filtration system, distributor, and gas control panel, providing an all-in-one solution.

*Tailored to different environments, we can provide silent systems for a peaceful operating environment at your site.

*We offer explosion-proof compressor systems for hazardous environments, ensuring safety and reliability.

Various structural forms to meet different customer demands

Compact Design

Frame integrated design, highly integrated, light weight and compact.

Fully automatic drain system and drain collection system, clean and environmentally friendly.

With electrical control system, economical and durable.

Silent Design

Vertical design, small footprint.

The cabinet with super silent design, low noise.

Aerodynamic design, efficient cooling channel, reserved air duct interface, can lead hot air to the outdoor.

Fully automatic drain system and drain collection system, clean and environmentally friendly.

Automatic PLC control system with HMI.

System Solutions

| Model | Suction Pressure Bar | Discharge Pressure Bar | Flow m3/min | Power kw | Dimensions mm | Weight kg |

| COMPACT design | ||||||

| NA1-6/15ETB | 6 | 15 | 1 | 3 | 1228*593*714 | 123 |

| NA1.5-6/15ETB | 6 | 15 | 1.5 | 4 | 125 | |

| NA2-6/15ETB | 6 | 15 | 2 | 5.5 | 128 | |

| NA1-6/25ETB | 6 | 25 | 1 | 5.5 | 126 | |

| NA1.5-6/25ETB | 6 | 25 | 1.5 | 7.5 | 130 | |

| NA0.5-6/30ETB | 6 | 30 | 0.5 | 4 | 125 | |

| NA1-6/30ETB | 6 | 30 | 1 | 5.5 | 128 | |

| NA1.5-6/30ETB | 6 | 30 | 1.5 | 7.5 | 130 | |

| NA0.5-6/50ETB | 6 | 50 | 0.5 | 4 | 128 | |

| NA1-6/50ETB | 6 | 50 | 1 | 7.5 | 130 | |

| NA0.5-6/100ETB | 6 | 60-100 | 0.5 | 5.5 | 128 | |

| NA0.B-6/100ETB | 6 | 60-100 | 0.8 | 7.5 | 130 | |

| NA0.5-6/200ETB | 6 | 100-200 | 0.5 | 7.5 | 132 | |

| NA0.5-6/350ETB | 6 | 200-350 | 0.5 | 7.5 | 132 | |

| SILENT design | ||||||

| NA0.5-6/100ETB | 6 | 60-100 | 0.5 | 5.5 | 1100*720*1365 | 272 |

| NA0.8-6/100ETB | 6 | 60-100 | 0.8 | 7.5 | 273 | |

| NA0.5-6/200ETB | 6 | 100-200 | 0.5 | 7.5 | 273 | |

| NA0.5-6/350ETB | 6 | 200-350 | 0.5 | 7.5 | 273 | |

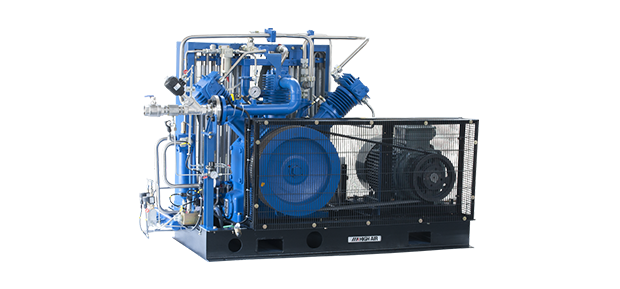

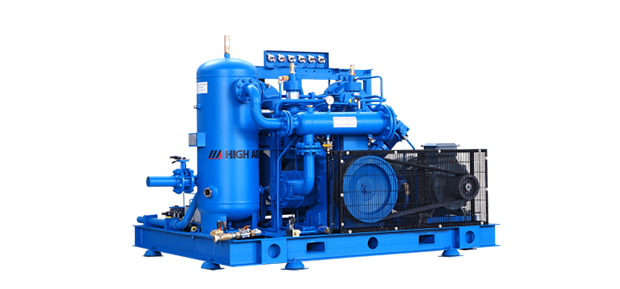

HGB Series Booster Compressors

High Air HGB Series Booster Compressors utilize reliable compression units and modular design, offering various main unit and cylinder options. Rational matching of compression ratios and cylinder sizes ensures low compression ratios at each stage and low operating temperatures.

*Operating pressure range: 2 MPa to 50 MPa

*Comprehensive intake protection, with real-time monitoring of intake pressure, discharge pressure, and temperature

*Fully automatic PLC control system enables unmanned operation of the unit

*Multiple drive options, whether electric motor or diesel engine driven, ensuring efficient operation of the unit

*Different exhaust filtration and drying systems can be selected based on specific requirements, achieving various cleanliness and dryness levels.

*Fully integrated design, with all components mounted on a common base, allowing installation without a foundation and meeting the requirements for mobile operations.

The HGB Series Booster Compressors fromHigh Air provide reliable and efficient performance, fulfilling various compression demands for air and nitrogen, and offering versatile solutions for different industrial applications.

Design Features

Our standardized modular design offers more flexibility and convenience in adjusting pistons, cylinders, cylinder heads, and valve components, enabling us to provide customers with efficient and economical systems. The design characteristics and advantages of our units ensure their enduring performance and gain approval from users.

*Easy installation and maintenance

*Low maintenance requirements and operating costs

*No special foundation requirements

*High operating efficiency

*Designed for continuous operation, suitable for heavy-duty work

*Well-balanced design with low vibration

*Low operating speed, long service life

*Low compression ratio and temperature rise

*Low operating noise

*Low speed for extended lifespan

These design features make our units capable of withstanding the test of time and being highly regarded by our customers. The combination of ease of installation, low maintenance, and long-lasting performance makes our systems a reliable choice for various industrial applications.

Multiple Solutions

*Diesel Engine Driven

*Dual-drive System (Electric and Diesel)

*Power Take-off (PTO) Driven Vehicle-mounted Compressor

*Direct Drive Compressor

*Water-cooled Cooling System

*Fully Integrated Containerized Solution

*Silent Unit Design

*Low-temperature Package for Severe Cold Environments

*Integral Explosion-proof Design

*Marine Design

These diverse solutions cater to various requirements and operating environments, providing customers with a range of options to suit their specific needs. Whether it's for industrial applications on land, in harsh cold climates, or marine environments, our compressors are designed to meet the challenges and deliver reliable and efficient performance.