HA Series Mid-to-High-Pressure Compressors

The HA Series mid-to-high-pressure air compressors are characterized by their small size, light weight, good balance, and low noise. They are widely used in various industrial applications.

Multiple blocks to meet different needs

W-max. pressure 350Bar X- max. pressure 420Bar

Various structural forms to meet different customer demands

COMPACT Design

í˝Frame integrated design, highly integrated,lightweight and compact.

í˝Fully automatic drain system and drain collection system, clean and environmentally friendly.

í˝With electrical control system, economical and durable.

í˝Optional wheel assembly for easy movement.

SILENT Design

í˝Vertical design, small footprint.

í˝The cabinet with super silent design, low noise.

í˝Aerodynamic design, efficient cooling channel, reserved air duct interface, can lead hot air to the outdoor.

í˝Fully automatic drain system and drain collec-tion system, clean and environmentally friendly.

í˝Automatic PLC control system with HMI.

í˝Optional integrated refrigerated dryer.

| Model | Pressure Bar | Flow m3/min | Power kw | Dimensions mm | Weight kg |

| COMPACT design | |||||

| HA0.1-330/ET | 330 | 0.1 | 3 | 706*376*432 | 49 |

| HAO.5-30/ETC | 30 | 0.5 | 5.5 | 1228*593*714 | 130 |

| HAO.35-80/ETC | 50-80 | 0.35 | 5.5 | 136 | |

| HAO.3-250/ETC | 100-250 | 0.3 | 7.5 | 138 | |

| HAO.3-350/ETC | 250-350 | 0.3 | 7.5 | 140 | |

| HA1-40/ETC | 40 | 1 | 15 | 1650*660*950 | 350 |

| HA0.85-70/ETC | 50-70 | 0.85 | 11 | 345 | |

| HA0.65-150/ETC | 80-150 | 0.65 | 11 | 345 | |

| HA0.6-250/ETC | 150-250 | 0.6 | 11 | 345 | |

| HA0.6-250/ETC | 250-400 | 0.6 | 15 | 350 | |

| SILENT design | |||||

| HA0.5-30/ESC | 30 | 0.5 | 5.5 | 1100*720*1365 | 264 |

| HAO.35-80/ESC | 50-80 | 0.35 | 5.5 | 270 | |

| HAO.3-250/ESC | 100-250 | 0.3 | 7.5 | 272 | |

| HAO.3-350/ESC | 250-350 | 0.3 | 7.5 | 273 | |

| HA1-40/ESC | 40 | 1 | 15 | 1400*850*1660 | 490 |

| HAD.85-70/ESC | 40-70 | 0.85 | 11 | 485 | |

| HAD.65-150/ESC | 80-150 | 0.85 | 11 | 485 | |

| HAO.6-250/ESC | 150-250 | 0.6 | 11 | 485 | |

| HAO.6-400/ESC | 250-400 | 0.6 | 15 | 490 | |

| |||||

High Pressure Storage Cylinders High Pressure Distributor

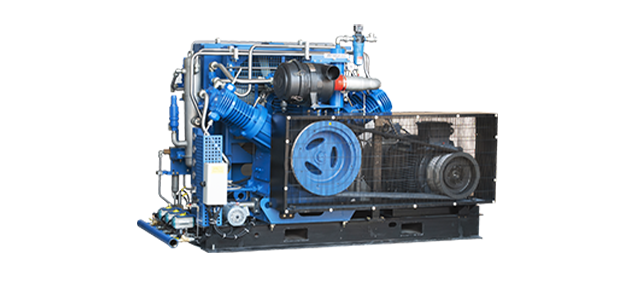

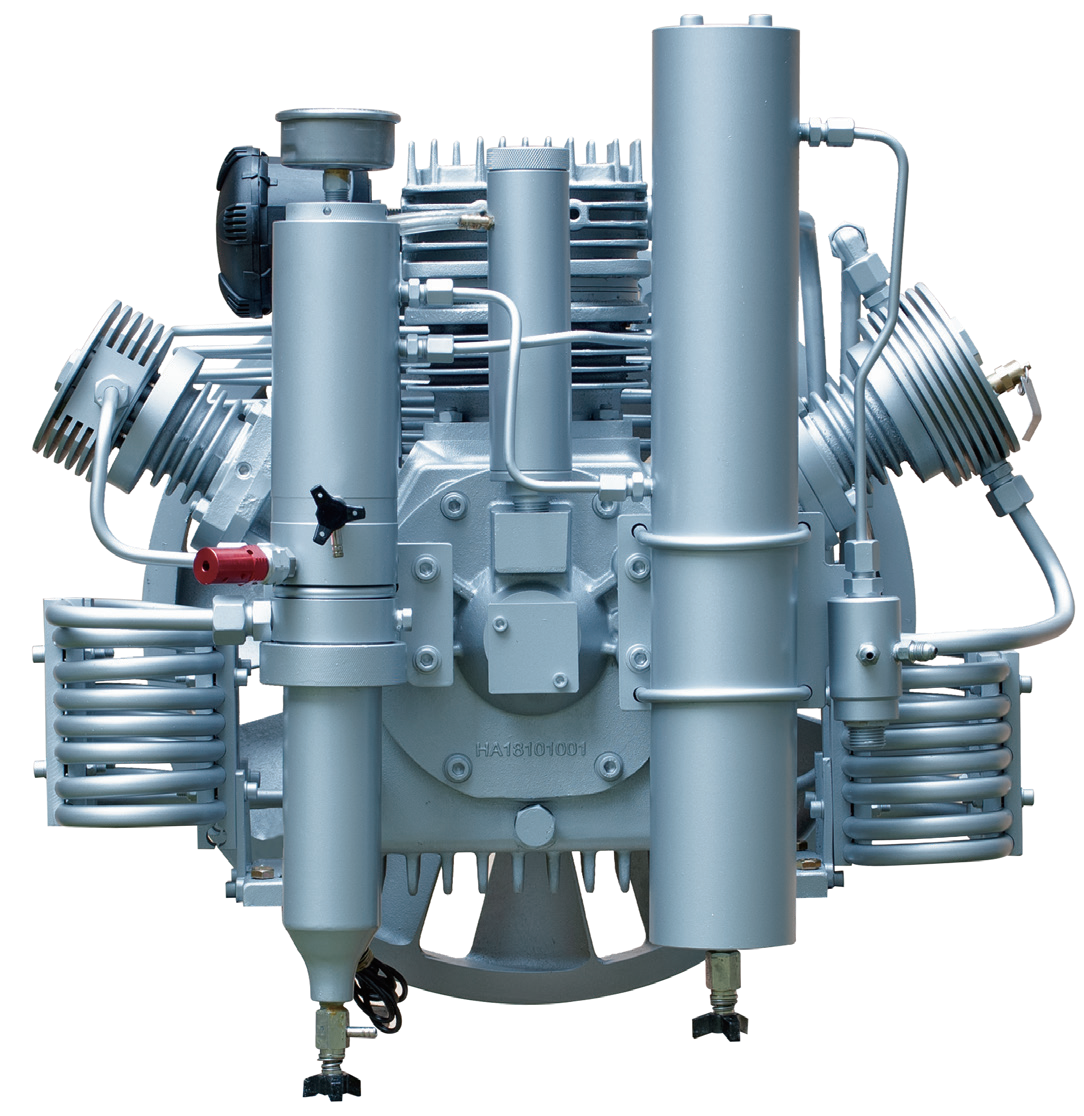

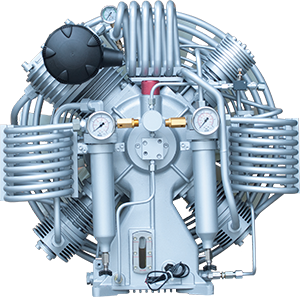

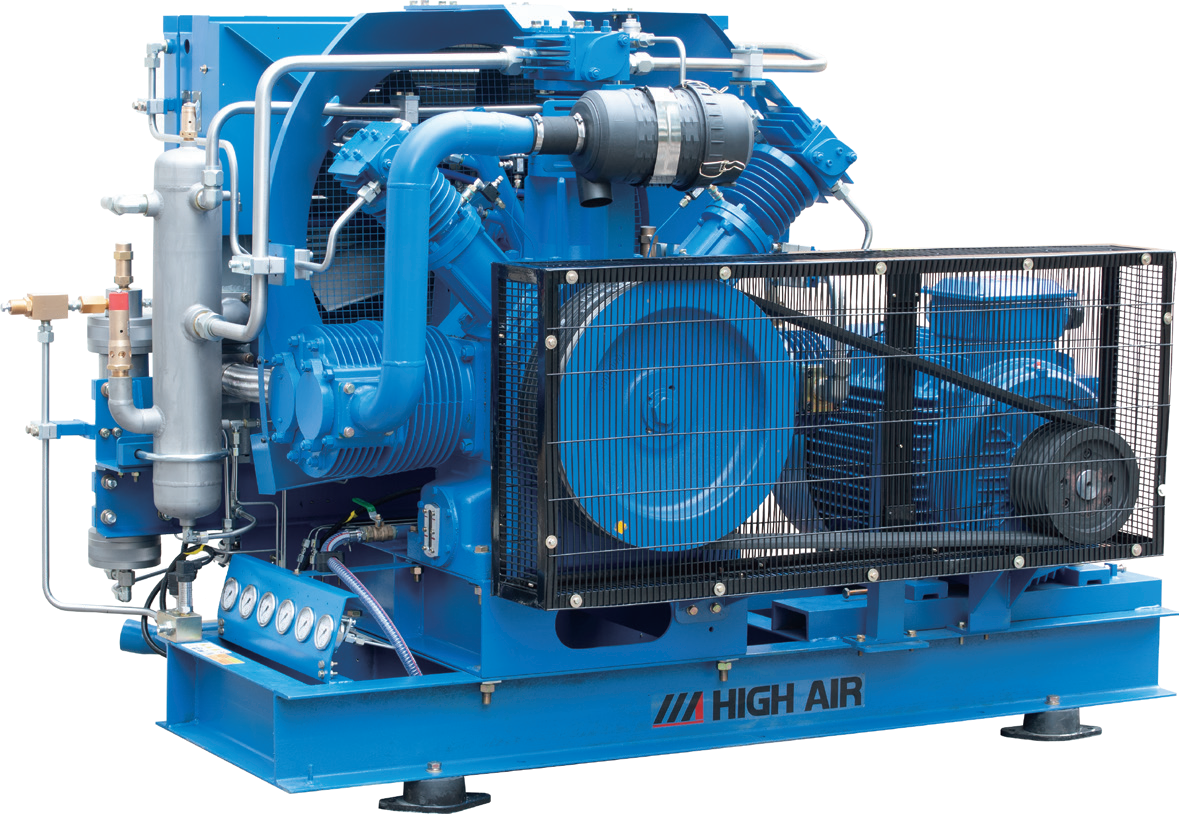

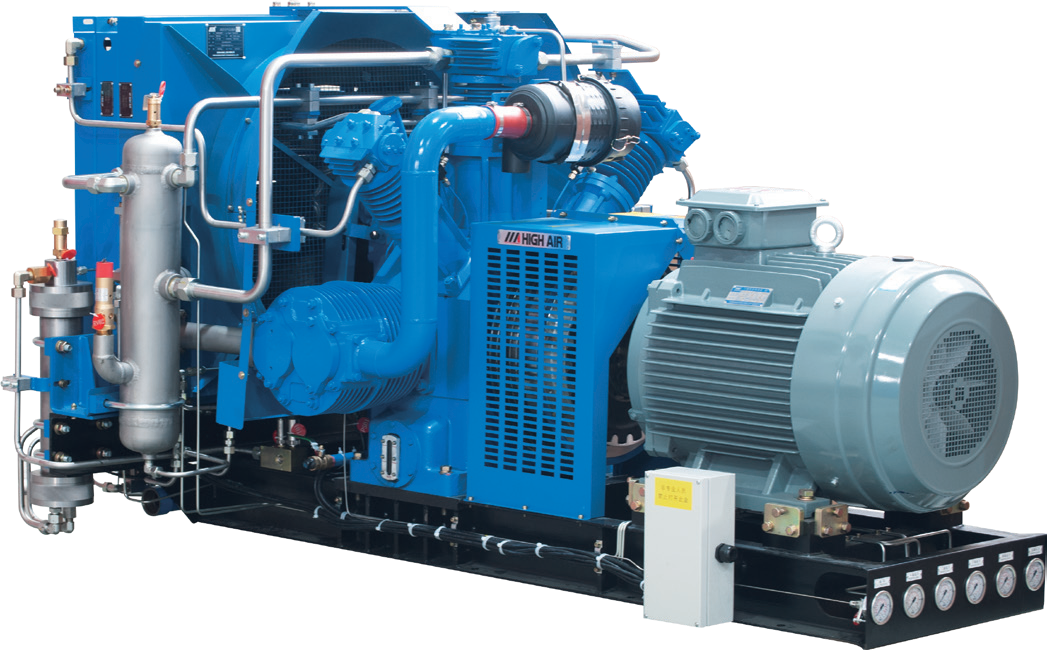

HG Series Mid-to-High-Pressure Compressors

The HG series medium and high pressure air compressors adopt a heavy-duty design, and various models meet diverse application needs.

Multiple blocks to meet different needs

V-max. pressure 450Bar W-max. pressure 500Bar

Air-cooled blocks, designed specifically for complex and demanding operating environments. Multi-stage compression reduces the load on each stage, and single-acting, deep-fin cylinders increase the reliability of the unit's operation.

Carefully selected components are suitable for various operating conditions.

The oil pump-driven lubrication system provides perfect lubrication to all moving parts. The lubricating oil monitoring system ensures the reliable operation of the unit. The lubricating oil filtration system precisely filters the lubricating oil, ensuring the safety of the unit.

Deep-fin cylinders and cylinder head cooling fins, along with oversized design coolers, effectively lower the operating temperatures at each stage.

The crankshaft drives the cooling fan to provide forced cooling for the main unit and air-cooled coolers.

The efficient inter-stage cooling system reduces the exhaust temperature at each stage of the unit.

The choice of air-cooled or water-cooled coolers can be tailored to the actual working conditions. Each cooling stage is equipped with a separator and fully automatic drainage system.

High Air offers standard control systems or can customize unique control systems according to customer requirements. Thanks to its reliable design, High Air compressors operate efficiently and stably under continuous or intermittent working conditions.

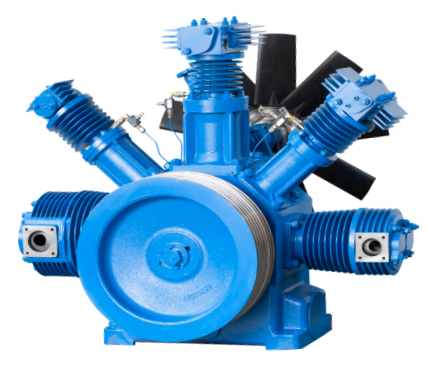

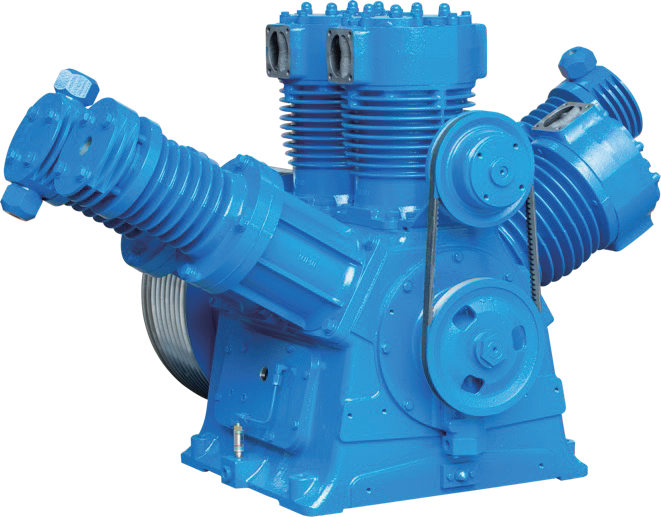

Design Features

Our standardized modular design provides more flexibility and convenience in adjusting the combination of pistons, cylinders, cylinder heads, and valves, enabling us to offer customers more efficient and economical systems. Our design features and advantages ensure that our units stand the test of time and gain recognition from users.

Easy installation and maintenance

Good balance and low vibration

Low maintenance workload and operating costs

Low compression ratio and temperature rise

No special foundation requirements

High operating efficiency

Designed for continuous operation, suitable for heavy-duty work

Low operating speed, long service life

Maximum pressure up to 500Bar

Low operating noise

These design characteristics allow our compressors to meet various operational demands effectively and make them highly reliable and user-friendly for our customers.

Multiple Solutions

Diesel Engine Driven

Dual-drive System (Electric and Diesel)

Power Take-off (PTO) Driven Vehicle-mounted Compressor

Direct Drive Compressor

Water-cooled Cooling System

Fully Integrated Containerized Solution

Silent Unit Design

Low-temperature Package for Severe Cold Environments

Integral Explosion-proof Design

Marine Design

These diverse solutions cater to various requirements and operating environments, providing customers with a range of options to suit their specific needs.

| Model | Pressure Bar | Flow m3/min | Motor kw | Dimensions mm | Weight kg |

| HG1.2-50 | 50 | 1.2 | 18.5 | 1600x935x1052 | 350 |

| HG1.5-50 | 50 | 1.5 | 22 | 1600x1030x1180 | 560 |

| HG2-50 | 50 | 2 | 30 | 1800x1000x1200 | 1150 |

| HG2.5-50 | 50 | 2.5 | 37 | 1800x1000x1200 | 1170 |

| HG3-50 | 50 | 3 | 45 | 2070x1100x1430 | 1400 |

| HG4-50 | 50 | 4 | 55 | 2070x1100x1430 | 1470 |

| HG1.2-70 | 70 | 1.2 | 18.5 | 1600x935x1052 | 350 |

| HG1.5-70 | 70 | 1.5 | 22 | 1600x1030x1180 | 560 |

| HG2-70 | 70 | 2 | 30 | 1800x1000x1200 | 1150 |

| HG2.5-70 | 70 | 2.5 | 37 | 1800x1000x1200 | 1170 |

| HG3-70 | 70 | 3 | 45 | 2170x1310x1460 | 1350 |

| HG4-70 | 70 | 4 | 55 | 2270x1310x1460 | 1550 |

| HG1-100 | 100 | 1 | 22 | 1600x1030x1180 | 550 |

| HG2-100 | 100 | 2 | 37 | 1850x1060x1200 | 1180 |

| HG3-100 | 100 | 3 | 55 | 2270x1310x1460 | 1550 |

| HG4-100 | 100 | 4 | 75 | 2270x1310x1460 | 1600 |

| HG6-100 | 100 | 6 | 110 | 3060x1980x1910 | 4650 |

| HG8-100 | 100 | 8 | 132 | 3060x1980x1910 | 4820 |

| HG1-150 | 150 | 1 | 22 | 1600x1030x1180 | 550 |

| HG1.5-150 | 150 | 1.5 | 30 | 1800x1140x1200 | 1050 |

| HG2-150 | 150 | 2 | 37 | 1800x1140x1200 | 1100 |

| HG3-150 | 150 | 2.8 | 55 | 2220x1280x1460 | 1600 |

| HG5-150 | 150 | 5 | 90 | 2420x1650x2130 | 3000 |

| HG6-150 | 150 | 6 | 110 | 3060x1980x1910 | 4650 |

| HG7-150 | 150 | 7 | 132 | 3060x1980x1910 | 4820 |

| HG1-250 | 250 | 1 | 22 | 1600x1030x1180 | 550 |

| HG1.5-250 | 250 | 1.5 | 37 | 1800x1140x1200 | 1100 |

| HG2-250 | 250 | 2 | 45 | 2220x1280x1460 | 1600 |

| HG3-250 | 250 | 2.8 | 55 | 2220x1280x1460 | 1600 |

| HG4-250 | 250 | 4 | 90 | 2420x1650x2130 | 3000 |

| HG5-250 | 250 | 5 | 110 | 3130x2140x1910 | 4800 |

| HG6-250 | 250 | 6 | 132 | 3130x2140x1910 | 5000 |

| HG1-350 | 350 | 1 | 22 | 1600x1030x1180 | 550 |

| HG1.5-350 | 350 | 1.5 | 37 | 1850x1060x1200 | 1180 |

| HG2-350 | 350 | 2 | 45 | 2300x1280x1430 | 1500 |

| HG2.5-350 | 350 | 2.5 | 55 | 2300x1280x1430 | 1570 |

| HG4-350 | 350 | 4 | 90 | 2420x1650x2130 | 3000 |

| HG5-350 | 350 | 5 | 110 | 3130x2140x1910 | 4800 |

| HG6-350 | 350 | 6 | 132 | 3130x2140x1910 | 5000 |

| HG1.5-400 | 400 | 1.5 | 37 | 2300x1280x1430 | 1470 |

| HG2-400 | 400 | 2 | 55 | 2300x1280x1430 | 1500 |

| HG4-400 | 400 | 4 | 90 | 2420x1650x2130 | 3000 |

| HG5-400 | 400 | 5 | 110 | 3130x2140x1910 | 4800 |

| HG6-400 | 400 | 6 | 132 | 3130x2140x1910 | 5000 |

| All size parameters are for air-cooled beit drive units. | All parameters are subject to change without prior notice. | ||||